Slot Hood Design

- The slotted hood takes advantage of a slot’s ability to distribute air extraction across a wide area, increasing the influence of air extraction across the full length of a lathe.

- Ventaire’s slotted fume hoods are the ideal solution for capturing welding fumes in stationary applications such as welding booths or tables. Positioned along the wall or mounted to the back of tables, the slotted fume hoods are designed to draw the fumes away from the welding fume source opposite of the breathing zone.

You’ll appreciate the solid construction and durable welded joints of our galvanized steel, stainless steel, aluminum and thermoplastic industrial ventilation hoods, each built to a specific size. A wide range of styles meets virtually any exhaust application—from vehicle maintenance to wastewater treatment to manufacturing. Single-piece construction is available up to any size that will fit on a truck and larger sizes are available in multiple sections for field assembly.

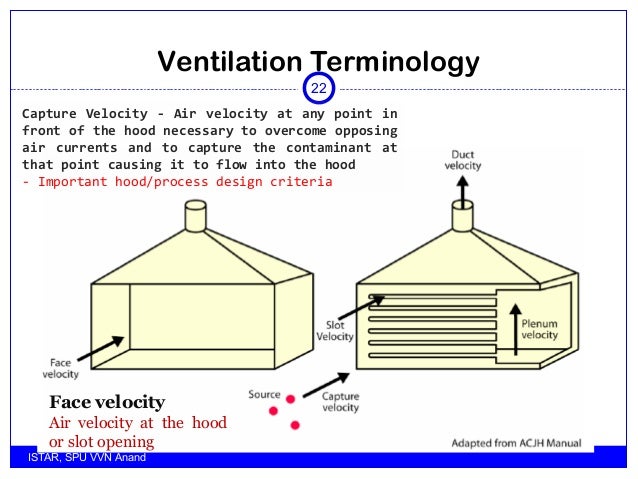

Always check local regulations before design. Capture velocity - v 1 - for an exhaust hood can be estimated with the empirical equation. V 1 = q / 2 y 2 c (1) where. V 1 = capturing velocity (m/s) q = air volume flow (m 3 /s) y = distance between table and exhaust hood (m) c = circumference of the hood (m). This design will do little or nothing for capture of fumes evolving from parts as they move above the capture range of the exhaust slot. Lip exhaust hoods work well with a push system as long as the slot, or slots, are within a height of.14 times tank width and obstructions are kept to a minimum.

- Keep work environments free of harmful vapors, fumes, oils, particles and more

- Expertly designed with heavy-duty, high-quality materials

- Options and accessories offer customized design

Standard Construction

- 18-gauge galvanized steel

- 18-gauge 304 or 316 stainless steel

- .063' aluminum

- Thermoplastic materials (e.g. PVC, CPVC, PE and PP)

- Welded seams

KEY

Models

Other Information

- Installation and Maintenance Manual (PDF)

Options & Accessories

- Internal baffles

- Perimeter slot

- Double shell

- Dampered slot

- Side skirt

- Gutter and drain fitting

- Filter rack

- Mounted switch

- Light fixture

- Make-up air plenum

materials

- Galvanized steel

- 304 stainless steel

- 316 stainless steel

- Aluminum

- Polyvinyl Chloride (PVC)

- Chlorinated Polyvinyl Chloride (CPVC)

- Polyethylene (PE)

- Polypropylene (PP)

finishes

- Mill (Thermoplastic is only available in mill finish)

- Satin polish (only available in stainless steel)

- Prime coated

- Two-part polyurethane paint (standard and custom colors available)

- Other paint finishes available such as epoxy or phenolic resin

Paint finishes

Available in twelve standard colors as well as any custom color. Shown below are representations of the standard colors*.

*Colors shown are an approximation, each computer monitor displays color differently.

Application Information

For additional information regarding industrial hood applications refer to:

Industrial Ventilation Manual

American Conference of Governmental Industrial Hygienists

Cincinnati, OH 45211

513-742-2020

www.acgih.org

ASHRAE Handbooks

American Society of Heating, Refrigeration and Air Conditioning Engineers, Inc.

1791 Tullie Circle, N.E.

Atlanta, GA 30329

404-636-8400

www.ashrae.org

Customization

Custom hoods are available fabricated to customer supplied requirements. FAX or e-mail a sketch or drawing to KEES for quotation.

Some examples of custom fabricated hoods are:

- Backshelf hood with front extension and flexible curtains

- Backshelf hood with pad filter frames

- Barrel filling hood

- Conical overhead hood

- Downdraft table

- Equipment enclosure

- Melting furnace hood

- Spray booth

WHICH LOSSES WOULD YOU EXPECT TO BE THE MOST SIGNIFICANT IN A LOCAL EXHAUST SYSTEM?

Most significant loss in a Local Exhaust System:| Hood Entry Loss |

| Friction Losses |

| Branch Losses |

SEE FIGURE BELOW. WHAT INDIVIDUAL LOSSES CAN YOU IDENTIFY?

Losses:| Hood |

| Elbow |

| Friction |

| Entry |

| Entry Loss to Fan |

| Stack |

WHAT IS THE FRICTION LOSS (IN INCHES OF WATER) OF STANDARD AIR FLOWING THROUGH A 5 INCH DUCT AT V = 4,000 FPM?

Solution:

From I.V. Manual, Table 5-5

At D = 5' and Duct Velocity = 4,000 FPM : Vp=1' wg

Duct Friction Loss = 0.054*Vp per foot = 0.054' wg per foot

Friction Loss: 0.054' wg per foot

WHAT IS THE FRICTION LOSS IN TERMS OF VELOCITY PRESSURE (VP)?

Solution:

Again, from Appendix A - Chart 5 or I.V. Manual

Friction Loss: 0.054' wg per foot

FOR THE FOLLOWING GRINDING WHEEL HOOD SYSTEM, CALCULATE (a) AIR VOLUME, (b) DUCT VELOCITY AND (c) PERCENT LOSS IN VELOCITY HEAD.

Given: Ce = 0.78

SPh = 2.50 inches water

DUCT DIAMETER = 5 inches

DUCT AREA (A) = 0.136 sq. ft.

Solution:

(a) Air Volume (Q) = V x A = 4005ÖVP x A = 4005 x Ce ÖSPh x A

= 4005 x 0.78 x Ö2.50 x 0.136 = 672 CFM

(b) Duct Velocity (V) = V = Q / A = 672 / 0.136 = 4950 FP

(c) Percent loss in Velocity head:

VP = (V/4005)² = (4950 / 4005)² = 1.52' WG

Static Pressure (SPh) = VP + he or 2.50 = 1.52 + he;

Hood entry loss (he) = 2.50 - 1.52 = 0.98' WG

Slot Hood Design Ideas

Hood entry loss factor (Fh) = (he / VP) = (0.98 / 1.52) = 0.645

Percent loss in Velocity head = Fh x 100 = 0.645 x 100 = 64.5%

IN A SIMPLE HOOD SHOWN BELOW, THE HOOD STATIC PRESSURE IS EQUAL TO THE VELOCITY PRESSURE IN THE DUCT PLUS THE HOOD ENTRY LOSS. IF THE FACE VELOCITY (Vf) IS 250 FPM AND DUCT VELOCITY (Vd) IS 3000 FPM, CALCULATE HOOD STATIC PRESSURE (SPh).

Solution:

Face Velocity (Vf) = Q / A face = 250 FPM

Duct Velocity (Vd) = Q / A duct = 3000 FPM

VPd = (Vd / 4005 )² = 0.56 ' WG

Fh (From Chart 18) = 0.25

SPh = Hood entry loss of transition (Hed = Fh x VPd) + VPd

= (0.25 x 0.56 ) + o.56

= 0.70 ' WG

FILL IN THE BLANKS:

| SQUARE. | 12* | 4005 | -2.00 | |||||

| CIRCLE. | 2.182 | 3000 | -2.50 | |||||

| CIRCLE. | 14 | 3000 | -0.86 | |||||

| CIRCLE. | 393 | -0.70 | 0.25 | |||||

| CIRCLE. | 30 | 2000 | -3.64 | |||||

| CIRCLE. | 4005 | 2184 | -5.20 |

Problem A:

Given: L = 12 inch, SP = - 2.00 inch Q = 4005 CFM

A = 1’ x 1’ = 1 Sq. Ft.

Q = V / A or 4005 = V / 1’ x 1’ or V = 4005 FPM

From Appendix A - Chart 5 or I.V. Manual, Table 5.7B

At V = 4005 FPM, VP = 1 inch wg

TP = SP + VP

= - 2.00 + 1.00 = -1.00 inch wg

Problem B:

Given: Area (A) = 2.182 Sq. Ft., V = 3000 FPM SP = -2.50 inch wg

Area = p D² / 4 or 2.182 = 3.14 D² / 4; D² = (2.182 x 4) / 3.14

Slot Hood Designer

D = 20 inch

From Appendix A - Chart 5 or I.V. Manual, Table 5-7B

At D = 20 inch and V = 3000 FPM, Q = 6000 CFM and VP = 0.57

TP = SP + VP

TP = -2.50 + 0.57 = -1.93 inch wg

FILL IN THE BLANKS

NOTE: ALL FLOW IN ROUND GALVANIZED DUCTS AT STP.

Solution:Problem A:

Given: D = 6 inch, V = 2000 FPM

From Appendix A - Chart 5 or I.V. Manual, Tables 5-5 and 5-7B

At D = 6 inch and V = 2000 FPM

Q = 350 CFM, FLF = 0.45 VP/Foot , VP = 0.25 inch WG and

Friction Loss = 0.0456*0.25= 0.0114 inch WG/ft

Problem B:

D = 8', VP = 0.01 inch WG,

Friction Loss Factor = 0.0321 Vp/ft

Friction Loss = 0.000321 inch WG/ft

Problem C:

Q = 15926.4CFM, VP = 3.2 inch WG,

Friction Loss Factor = 0.0096 VP/ft

Friction Loss = 0.31inch WG/ft

Problem D:

Q = 1600 CFM, V = 566 FPM, D= 23 inch

Friction Loss Factor = 0.0088 VP/ft

Friction Loss = 0.00018inch WG/ft

WHAT IS THE ACTUAL LOSS IN INCHES WG OF AIR FLOWING THROUGH A THREE-PIECE, 60° AND 45° ELBOW (R/D = 1.25) AT Vd = 3,500 FPM.

Solution:| Given: Three piece, 60° Elbow, R/D = 1.25 Vd = 3,500 FPM |

Elbow Loss Factor for angles < 90° , Kf = (f / 90° ) x K90

Loss Coefficient = (0.42+0.34)/2 = 0.38

Therefore, Kf = (60 / 90) x 0.42 = 0.25 inch WG

From Appendix A - Chart 5 or I.V. Manual, Table 5-7B

At Duct Velocity Vd = 3,500 FPM, Velocity Pressure VP = 0.765

Elbow Loss = ( K x VP )

Elbow Loss= 0.25 x 0.76 = 0.19 inch WG| For 45° , three-piece elbow: |

Elbow Loss= 0.14 x 0.76 = 0.11 inch WG

WHAT IS THE ACTUAL LOSS IN INCHES OF WG FOR A BRANCH ENTRY OF 30° WHERE THE ENTRY VELOCITY IS 4,500 FPM?

Solution:

Given: V = 4,500 FPM

From Appendix A - Chart 5, VP = 1.26 Inch WG

(I.V Manual, Table 5-B)

From Appendix A - Chart 14, At 30° branch entry, K = 0.18

(I.V Manual, Table 5-14)

Entry Loss (SPL) = 0.18 x 1.26 = 0.23 inch WG

SPL = 0.23 inch WG

WHAT IS THE ESTIMATED FLOW RATE THROUGH A HOOD IF Ce = 0.82, SPh = -2.0 INCHES WG, AND THE DUCT DIAMETER IS 12 INCHES?

Solution:

Coefficient of Entry (Ce) = e(VP / SPh)

Or SPh = VP / Ce² Or VP = Ce² x SPh

VP = (0.82)² x 2.0 = 0.67 x 2.0 = 1.34 inch WG

From Appendix A - Chart 7, At VP = 1.34, V = 4,636 FPM

From Appendix A - Chart 5, At V = 4,636 FPM, Q = 3.750 CFM

| A BELL MOUTH HOOD, IF THE DUCT VELOCITY = 3,000 FPM. |

From Appendix A - Chart 11A, Coefficient of Entry (Ce) = 0.98 and

Loss Factor (K) = 0.04

From Appendix A - Chart 7, At V = 3,000 FPM, VP = 0.56 inch WG

Ce = v ( VP / SPh ), SPh = (VP / Ce² ) = 0.56 / 0.98²

SPh = (0.56 / 0.96) = 0.58 inch WG

Hood Entry Loss (He) = SPh - VP = 0.58 - 0.56 = 0.02 inch WG| A ROUND TAPERED HOOD, INCLUDED ANGLE OF 90-DEGREES AND DUCT VELOCITY V= 2,300 FPM. |

From Appendix A - Chart 11 B, Fn = 0.15

(I.V. Manual-Fig 5-12)

From Appendix A - Chart 7, At V = 2,300 FPM, VP = 0.33 inch WG

He =Fn * Vp =0.15*0.33 = 0.05' WG

SPh = He + Vp = 0.05 + 0.33 = 0.38 inch WG

Ce = Sqrt(Vp/ SPh ) = 0.93| A ROUND PLAIN DUCT HOOD, IF DUCT VELOCITY = 3,750 FPM. |

From Appendix A - Chart 11 A, Ce = 0.72, Fn = 0.93

(I.V. Manual-Fig 3-16)

From Appendix A - Chart 7, At V = 3,750 FPM, VP = 0.875 inch WG

(I.V. Manual, Table 5-7B)

SPh = (0.875 / 0.72² ) = (0.875 / 0.52) = 1.68 inch WG

He = SPh - VP = 1.68 - 0.875 = 0.805 inch WG| IF AT A LATER DATE, THE HOOD STATIC PRESSURE FOR EACH OF THE ABOVE HOODS IS FOUND TO BE, SPh = -2.00 INCH WG, AND D = 12 INCH, WHAT IS THE ESTIMATED FLOW RATE (Q) IN EACH SYSTEM? |

Given: 19(a): D = 12', Ce = 0.98,

SPh = - 2.00 inch WG,

Area (A) = p r² = (3.14 x 36) / 144 = 0.78 Sq. Ft.

Q = 4005 Ce x eSPh *A = 4005 x 0.98 x v 2.00*0.78

Q = 4,360 CFM

A FLANGED DUCT HOOD IS TO BE USED TO CONTROL WELDING FUMES AND GASES. THE HOOD CAN BE MOVED WITHIN NINE INCHES OF THE WELDING POINT. THE PLANT MANAGER WOULD LIKE TO MAINTAIN A CAPTURE VELOCITY AT THE WELDING POINT OF 150 FPM. WHAT Q WOULD YOU SUGGEST?

Solution:

From Appendix A - Chart 11C (Welding Hood, Portable…)

Q = 2 p X² Vc = 2 x 3.14 x (9/12)² x 150

Q = 530 CFM

WHAT CAPTURE VELOCITIES ARE RECOMMENDED FOR THE FOLLOWING OPERATIONS?

Solution:| ARC WELDING 100 FPM |

| GRINDING WHEEL WITH A GOOD ENCLOSURE 200 - 500 FP |

| LAB FUME HOOD 100 FPM |

FOR THE BOOTH SHOWN, FIND THE TARGET AIRFLOW (Qt), GIVE THAT ITS FACE VELOCITY (Vf) = 100 FPM.

Solution:

Area = 6' x 8' = 48 Sq. ft.

Qt = Vf x A = (100 ft/min) x (48 Sq. ft.)

Q = 4800 CFM

FIND Qt, GIVEN THAT Vf = 125 FPM

Solution:

Area (A) = 5' x 3' = 15 Sq. ft.

Qt = Vf x A = (125 ft./min.) x (15 Sq. ft.)

Qt = 1875 CFM

FIND Q, GIVEN THAT: DUCT VELOCITY (Vd) = 2510 FPM, DUCT DIAMETER (D) = 24'

Solution:

Area = p D² / 4 = 3.14 x 24 x 24 /4 Sq. Inch

= 3.14 x 24 x 24 / 4 x 12 x 12= 3.14 Sq. ft.

Q = (Vd) x A = (2510 ft/min.) x (3.14 Sq. Ft.)= 7885 CFM

Q = 7885 CFM

FIND Q GIVEN THAT: DUCT DIAMETER (D) = 6', AND DUCT VELOCITY (Vd) = 3550 FPM

Solution:

Area (A) = p D² / 4 = 3.14 x 6 x 6 / 4 x 12 x 12= 0.1963 Sq. Ft.

Q = (Vd )x A = (3550 ft./min.) x (0.1963 Sq. Ft.)= 697 CFM

Q = 697 CFM

FIND THE AIRFLOW IN THE MAIN DUCT:

Solution:

Q = V x A = (2890 ft./min.) x (Area of 10' duct)

= (2890) x (p D² / 4)

= 2890 x 3.14 x 10 x 10 / 4 x 12 x 12

= 2890 x 0.5454 = 1576 CFM

Q = 1576 CFM

FIND DUCT VELOCITY (Vd) GIVEN THAT: Q = 7885 CFM AND DUCT DIAMETER = 24'

Solution:

Area (A) = 3.14 x 24 x 24 / (4 x 12 x 12)

= 3.14 Sq. Ft.

Slot Hood Design Guide

Duct Velocity (V) = Q / A = 7885 / 3.14

= 2510 ft./min.

V = 2510 FPM

FIND DUCT VELOCITY (Vd) GIVEN THAT Q = 697 CFM AND D = 6'

Solution:

Area = 3.14 x 6 x 6 / (4 x 12 x 12) = 0.1963 Sq. Ft.

V = Q / A = 697 / 0.1963

= 3551 FPM

V = 3551 FPM

CHOOSE A DIAMETER SUCH THAT Vd ³ 3500 FPM AND THEN CALCULATE THE ACTUAL DUCT VELOCITY.

Solution:

Area (At) = Qt /Vt = (697 CFM) / (3500 FPM) = 0.1991 Sq. Ft.

Also, Area = 3.14 x D² / 4 x 12 x 12 = 0.1991

D² = 0.1991 x 4 x 12 x 12 / 3.14

D = 24 x Ö (0.1991 / 3.14) = 6.04'

Since we must choose either a 6' or 7' diameter duct, then duct velocity (Vd) will not exactly equal to Vt. Let us calculate the duct velocity for both:

V = Q / A

For 6' diameter duct

V = 697 / 3.14 x 6 x 6 / 4 x 12 x 12 = 697 x 0.1963 = 3551 FPM

For 7' diameter duct

V = 697 / 3.14 x 7 x 7 / 4 x 12 x 12 = 697 x 0.2673 = 2608 FPM

If Q = Qt, to ensure that Vd > Vt, choose the smaller diameter.

(Alternate Solution: Let V = Vt, Q = Vt x Area of larger duct

Q = 3500 x 3.14 x 7 x 7 / 4 x 12 x 12 = 935 CFM)

FOR THE SYSTEM SKETCHED BELOW, CHOOSE THE DUCT DIAMETERS AND COMPUTE THE DUCT VELOCITIES FOR BRANCHES 'a' AND 'b'.

Solution:

For Branch 'a':

Area (A) = Qa / Va = 1000 / 2500 = 0.40 Sqft.

Also, Area = p D² / 4 = 3.14 x D² / 4 x 12 x 12 S q. ft

Duct Diameter (Da) = Ö (0.40 x 4 x 12 x 12 / 3.14) = 8.56'

Choose Da = 8'

Area (A) = 3.14 (8 /4 x 12 x 12)² = 0.3491 Sq. Ft.

Va = Qa / Aa = 1000 /0.3491 = 2865 FPM

For Branch 'b':

Area (A) = Qb / Vb = 1000 / 4000 = 0.25 Sq. Ft.

Duct Diameter (Db) = 4 x 12 x 12 Ö (0.25 / 3.14) = 6.77'

Choose Db = 6'

Area (A) = 3.14 (6' / 4 x 12 x 12)² = 0.1963 Sq. Ft.

Vb = Qb / Ab = 1000 / 0.1963 = 5094 FPM

CHOOSE THE DUCT DIAMETER AND COMPUTE THE DUCT VELOCITY FOR THE MAIN DUCT, GIVEN THAT Vt = 2500 FPM.

Solution:

For the main duct:

Vt = Highest transport velocity upstream = 2500 FPM

Qm = Qa + Qb = 1200 + 805 = 2005 CFM

(we are interested in the actual Q, not Qt)

Area (A) = Qm / Vt = 2005 / 2500 = 0.802 Sq. Ft.

Diameter (Dt) = 4 x 12 x12 x Ö (0.802 / 3.14) = 12.13'

Choose Dm = 12'

Area = 3.14 (12'/24')² = 0.7854 Sq. Ft.

Vm = Qm / A = 2005 / 0.7854 = 2553 FPM

FOR THE SYSTEM SKETCHED BELOW, WHAT IS THE AVERAGE FACE VELOCITY?

Solution:

Assume that the density is constant in the duct, the Continuity Equation is

: A1 V1 = A2 V2 Q1 = Q2V2 = A1 V1 / A2= [p (8)² / 4] x 1000 / [p (4)² /4]

= 4000 FPM

V2 = 4000 FPM

FOR THE SYSTEM SKETCHED BELOW, WHAT IS THE AVERAGE FACE VELOCITY?

Solution:

From the Continuity Equation, V1 A1 = V2 A2

V2 = 2000 x (3.14 x 4 x 4 / 4) / 6 x 12

= 349 FPM

V2 = 349 FPM